Good building airtightness is achieved in 3 steps: Plan – Build – Check.

The building airtightness requirement is defined in the design phase of the building. The fundamental principle for designing good airtightness is to specify a combination of materials which constitute a continuous and tight plane of airtightness in the building envelope around the protected volume of the building. In horizontal and vertical sections, the designer must be able to follow this virtual tight plane with a pencil, without lifting it. The designer must identify the junctions that must be sealed and specify adequate tightening products and methods. Each junction between building components must be analysed to define the materials that will durably ensure airtightness at this location. The designer should draw the junctions at a scale of 1:5 to 1:10 for a detailed description of the tightening methods [1]. Based on the plans and descriptions, the craftsman can select suitable airtight materials and install the air barrier and connections in a professionally airtight manner. A quality check of the air barrier at 50 Pa negative pressure before its cladding, e.g. with gypsum board, enables a quick and cost-effective improvement if necessary. At the end of the construction process, an air tightness measurement is carried out in accordance with the standard (e.g. ISO 9972) to verify the requirement

Building Airtightness requirement

It is necessary to define the airtightness of the building during the planning phase. A Passive House for example must reach a better air permeability than “normal” buildings. Designer, planer, craftsmen etc. must know this in order to take care of it.

Air Tightness Concept

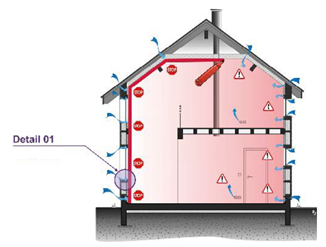

Even in the planning phase the required air barrier should be considered when choosing the type of construction. Similar to the thermal building envelope this protection layer, the air barrier, has to continuously enclose the entire heated volume. To plan the air barrier the building interior is marked with a red pen in one uninterrupted, continuous line.

Illustration of the principle of the airtight and continuous “air barrier” [1]

The red line forms the later air barrier. This procedure should be repeated for all floor plans and sections. For each exterior building component it has to be determined which layer of the building element will provide air tightness.

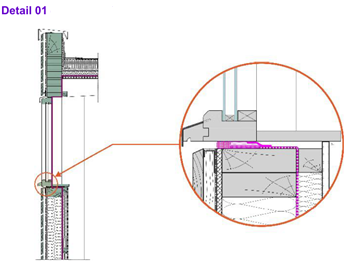

From Outline to Detail

The outline is followed by detail drawings of points of change in building components, material, or directions. Also mark the run of the air barrier in these detailed representations. Finally, plan where the airtight building component layers are lastingly connected airtight at their transitions.

Example of a detail including the air barrier [1]

Avoiding Penetrations

The number of necessary penetrations of the air barrier (wiring, pipes, electrical outlets in the external walls) should be kept to a minimum.

Air barrier: materials and installation methods

Based on the planning and the execution plans, craftsmen can install the air barrier. During implementation, the manufacturer's instructions on the airtightness of the materials and their way of installation must be observed, such as a dry and dust-free substrate when using adhesive tapes, etc.

Checking for leaks at 50 Pascal induced pressure

When the air barrier is completed, create a pressure difference between inside and outside of the building of ca. 50 Pa negative pressure with the test equipment (blower door). To check for leaks at building components use your hand, a thermoanemometer, a fog generator or an infrared camera. Create a leakage report and / or mark the leakages so that they easily can be found and sealed by the craftsmen.

Final measurement

At the end of the construction process, the air tightness measurement is performed according to the relevant standards (e.g. ISO 9972 in Europe). This measurement serves to verify whether the air tightness of the building envelope defined at the beginning is achieved and meets the desired requirements.

Many countries have developed guidelines to build airtight, some of them are listed in [2].

References

[1] Carrié F.R., Jobert R., Leprince V., "AIVC Contributed Report 14: Methods and techniques for airtight buildings", AIVC, 2012

[2] Leprince V., Kapsalaki M., Carrié F.R., "AIVC Ventilation Information Paper (VIP) 37: Impact of Energy Policies on Building and Ductwork Airtightness", AIVC, 2017

Posted in: Building Airtightness