What does ultra sound has to do with ventilation?

This may seem like a difficult question, but the answer is much more logical and valuable than it may seem at first. Over the past 5 years, the world has seen an increasing number of energy efficiency polices. These, combined with an increasing focus on indoor air quality, raise a demand for new technologies that can help optimize air quality and at the same time reduce energy consumption in buildings. This is where ultrasound becomes part of the picture.

Is the construction industry part of the problem?

Did you know that buildings are responsible for 40 % of the energy consumption and 36 % of the CO2 emissions in the EU? This might seem shocking to some and consequently, the EU has introduced new regulations, which state that the energy consumption must be reduced with 20 % by the year 2020. Europe is already at the forefront of energy efficiency policies. The newest EU regulations state that all new buildings must meet the minimum standards and contain high-efficient alternative energy systems.

At Lindab, we believe that regulations do not provide results on their own. To reach the goals, we need action and a willingness to think outside the box. One of the areas where alternative thinking can improve efficiency and the environmental impact is ventilation. However, we need to challenge the conventional thinking and old habits to find the possibilities.

Mismatch between air quality and energy consumption

An increased focus on energy savings has meant that ventilation systems with low volume flows have become increasingly common. This, in turn, has created a need for measuring instruments and methods with high accuracy even in low volume flow conditions.

Up until today ventilations systems have used inside measurers in the air ducts, which interfere with the airflow and collect dirt. This old technology does not seem efficient in a modern ventilation system. There seems to be a mismatch between optimal indoor climate and minimal energy consumption.

Lindab is not afraid of challenges and instead of looking at size, placement or use of measuring instruments, Lindab has looked for alternative solutions. A stabile, accurate and easy understandable measuring device creates a system, which can be controlled in the most optimal way. Self-diagnosis and presentation of the results provide users, house owners, and maintenance personal with the possibility to run the system optimally over the lifetime of the system.

This is where ultra sound as a measuring method becomes a valuable tool.

Ultra sound is a classical win-win

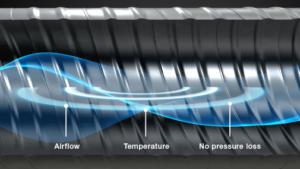

What if we imagine a ventilation system with a measuring instrument without any obstacles in the air stream? The benefits of such a system go beyond higher energy efficiency as the system also entails easier cleaning and maintenance of the system. Furthermore, ultra sound provides an exact measurement of the entire airflow range without causing pressure drops. The new ultra sound technology optimizes the airflow and the overall efficiency of the ventilation system by securing an uninterrupted airflow with reduced pressure drop.

Sensors mounted on the ventilation ducts measure the air flow and the temperature without any protruding parts that collect dirt and interfere with the airflow. This enables us to measure air velocity with high accuracy all the way down to 0,5 m/s. The exact measurements enable us to control and lower the overall consumption of air and thereby energy usage in a ventilation system. This all helps reduce the time and the money spent on ventilation systems – a classical win-win situation for the environment and the economy.

As stated in the beginning, it makes sense to think of ultra sound and ventilation as connected areas. If you would like to hear more about how we work with ultra sound in our ventilation systems, visit our website to read more about our patented product UltraLink.